+44 (0)1355 907 160

sales@bovill-boyd.co.uk

Rubber Mouldings & Extrusions

Introduction to rubber moulding and extrusion capabilities

Bovill & Boyd Engineering Ltd have over 50 years’ experience in the manufacturing of moulded and extruded rubber products. This experience gives us the ability to provide innovative production solutions, allowing us to facilitate long term partnerships with our customers, constantly delivering cost effective results.

Most of our senior staff have been involved in Rubber manufacturing for over 50 years and are well versed in all methods of rubber production. This give us an enviable edge when it comes to providing solutions for complicated, technical products. In addition to our experienced technical team, we have our own Rubber Mill and laboratory on site, which allows us to produce our own compounds. This provides added agility when it comes to compound/material manipulation, allowing us to pioneer innovative solutions to products required to perform in extreme environments or under very tight tolerances. We also have a fully digitised ingredient management system, that gives full batch traceability across the production processes.

We serve almost all Industries, including:

Oil & Gas

Offshore Pipelay

Aerospace and Defence

Hydraulics

Electronics

Rail

Food and Drink

Pharmaceutical

Press Shop Floor

Technical Capabilities

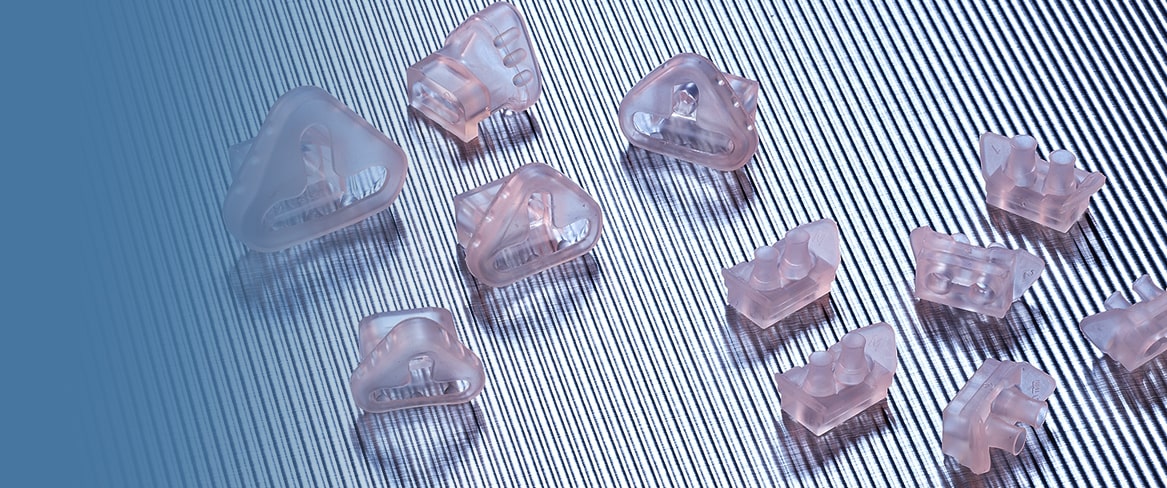

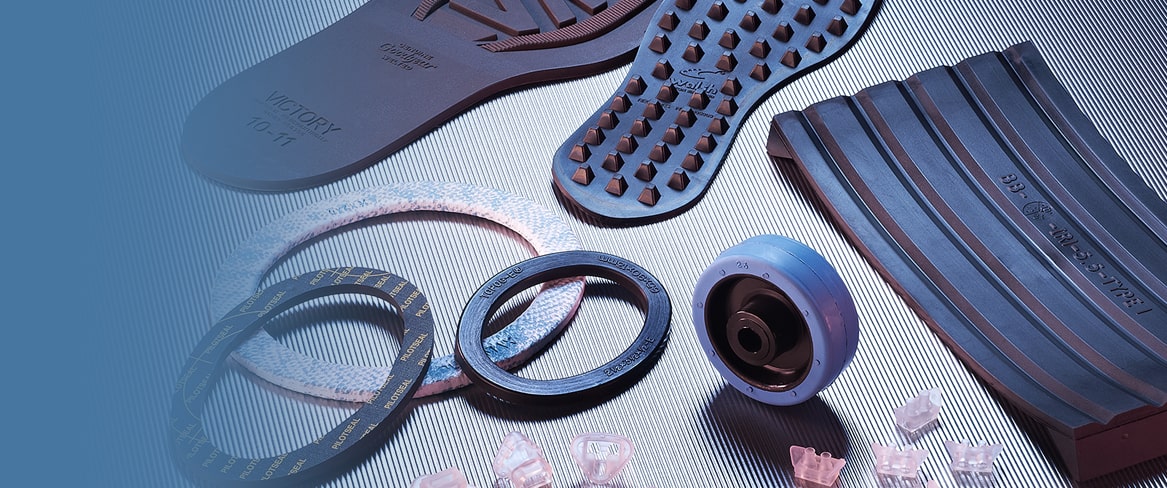

We have a wide range of rubber compression and injection moulding machinery at our disposal, in addition to several LSR & Injection plastic moulding machines. We are constantly reviewing our equipment to ensure we are at the cutting edge of technology innovation. We also work very closely with our supply partners giving us a unique insight into new machinery developments and opportunities.

As a result of this, we can produce a vast array of parts, supplying a wide range of industries and applications and with our years of experience, we are able to accommodate the majority of requirements, from LSR, Plastic and almost any rubber requirement. Please do not hesitate to contact our technical sales team to discuss any requirements you may have.

Obviously with our experience comes a need for on-site laboratory facilities, both to enable us to innovate with new compounds and solutions, but also to ensure production parts are within specification and tolerance. To this end, we are continually investing in our facilities and have developed partnerships with leading chemical scientists to ensure we are at the cutting edge of material and product development.

With our years of knowledge and experience we are able to provide a full tool design service, giving multiple options to most projects, allowing our customers to pick the most cost-effective solution. We have also built up a fantastic network of tooling partners that are able to accommodate all of our customers’ requirements.

Where there is an absence of technical part drawings, we are able to offer the ability to reverse engineer production solutions from just the finished part.

Ian Balfour meeting our machinery partner, Maplan in Vienna

Contact details for technical discussions/meetings

Our Technical Sales team are always happy to discuss enquiries – please do not hesitate to contact us:

Sales@bovill-boyd.co.uk

+44 (0)1355 907 160

Compound Tables

| Butyl (IIR) | |

|---|---|

|

Operating Temperature |

-45 to 150ºC |

|

Mechanical Strength |

Fair/Good |

|

Abrasion Resistance |

Good |

|

Flex Resistance |

Good |

|

Low Temp. Flexibility |

Good |

|

Ozone/Weather Resistance |

Excellent |

|

Water Resistance |

Excellent |

|

Impermeability to Gases |

Excellent |

|

Oil Resistance |

Poor |

|

Fuel Resistance |

Poor |

|

Resistance to Dilute Acid |

Excellent |

|

Resistance to Dilute Alkali |

Excellent |

|

Special Properties |

- |

| EPDM (EPDM) | |

|---|---|

|

Operating Temperature |

-50 to 140ºC |

|

Mechanical Strength |

Fair/Good |

|

Abrasion Resistance |

Fair |

|

Flex Resistance |

Fair |

|

Low Temp. Flexibility |

Good / Excellent |

|

Ozone/Weather Resistance |

Excellent |

|

Water Resistance |

Excellent |

|

Impermeability to Gases |

Good |

|

Oil Resistance |

Poor |

|

Fuel Resistance |

Poor |

|

Resistance to Dilute Acid |

Excellent |

|

Resistance to Dilute Alkali |

Good |

|

Special Properties |

- |

| Hypalon (CSM) | |

|---|---|

|

Operating Temperature |

-35 to 150ºC |

|

Mechanical Strength |

Good / Excellent |

|

Abrasion Resistance |

Good |

|

Flex Resistance |

Good |

|

Low Temp. Flexibility |

Fair / Good |

|

Ozone/Weather Resistance |

Excellent |

|

Water Resistance |

Good |

|

Impermeability to Gases |

Good / Excellent |

|

Oil Resistance |

Fair |

|

Fuel Resistance |

Poor / Fair |

|

Resistance to Dilute Acid |

Excellent |

|

Resistance to Dilute Alkali |

Excellent |

|

Special Properties |

Self extinguishing, good pigmentation |

| Natural (NR) | |

|---|---|

|

Operating Temperature |

-45 to 95ºC |

|

Mechanical Strength |

Excellent |

|

Abrasion Resistance |

Good / Excellent |

|

Flex Resistance |

Excellent |

|

Low Temp. Flexibility |

Good |

|

Ozone/Weather Resistance |

Poor / Fair |

|

Water Resistance |

Good |

|

Impermeability to Gases |

Fair |

|

Oil Resistance |

Poor |

|

Fuel Resistance |

Poor |

|

Resistance to Dilute Acid |

Good |

|

Resistance to Dilute Alkali |

Fair |

|

Special Properties |

- |

| Neoprene (CR) | |

|---|---|

|

Operating Temperature |

-35 to 110ºC |

|

Mechanical Strength |

Good / Excellent |

|

Abrasion Resistance |

Good |

|

Flex Resistance |

Good |

|

Low Temp. Flexibility |

Fair / Good |

|

Ozone/Weather Resistance |

Good |

|

Water Resistance |

Good |

|

Impermeability to Gases |

Good |

|

Oil Resistance |

Fair |

|

Fuel Resistance |

Poor / Fair |

|

Resistance to Dilute Acid |

Fair |

|

Resistance to Dilute Alkali |

Fair |

|

Special Properties |

Self extinguishing |

| Nitrile (NBR) | |

|---|---|

|

Operating Temperature |

-35 to 125ºC |

|

Mechanical Strength |

Good |

|

Abrasion Resistance |

Excellent |

|

Flex Resistance |

Fair |

|

Low Temp. Flexibility |

Fair / Good |

|

Ozone/Weather Resistance |

Fair |

|

Water Resistance |

Good |

|

Impermeability to Gases |

Good |

|

Oil Resistance |

Excellent |

|

Fuel Resistance |

Good |

|

Resistance to Dilute Acid |

Excellent |

|

Resistance to Dilute Alkali |

Good |

|

Special Properties |

Fuel and oil resistance |

| Polyurethane (PU) | |

|---|---|

|

Operating Temperature |

-50 to 90ºC |

|

Mechanical Strength |

Excellent |

|

Abrasion Resistance |

Excellent |

|

Flex Resistance |

Excellent |

|

Low Temp. Flexibility |

Good |

|

Ozone/Weather Resistance |

Excellent |

|

Water Resistance |

Fair |

|

Impermeability to Gases |

Good |

|

Oil Resistance |

Good / Excellent |

|

Fuel Resistance |

Good |

|

Resistance to Dilute Acid |

Fair |

|

Resistance to Dilute Alkali |

Good |

|

Special Properties |

Abrasion resistance |

| SBR (SBR) | |

|---|---|

|

Operating Temperature |

-40 to 95ºC |

|

Mechanical Strength |

Good |

|

Abrasion Resistance |

Excellent |

|

Flex Resistance |

Good |

|

Low Temp. Flexibility |

Good |

|

Ozone/Weather Resistance |

Poor / Fair |

|

Water Resistance |

Good |

|

Impermeability to Gases |

Fair |

|

Oil Resistance |

Poor |

|

Fuel Resistance |

Poor |

|

Resistance to Dilute Acid |

Fair |

|

Resistance to Dilute Alkali |

Fair |

|

Special Properties |

- |

| Silicone (VMQ) | |

|---|---|

|

Operating Temperature |

-60 to 300ºC |

|

Mechanical Strength |

Poor |

|

Abrasion Resistance |

Fair |

|

Flex Resistance |

Poor / Fair |

|

Low Temp. Flexibility |

Excellent |

|

Ozone/Weather Resistance |

Excellent |

|

Water Resistance |

Excellent |

|

Impermeability to Gases |

Poor |

|

Oil Resistance |

Poor / Fair |

|

Fuel Resistance |

Poor |

|

Resistance to Dilute Acid |

Fair |

|

Resistance to Dilute Alkali |

Fair |

|

Special Properties |

Heat resistance |

| Thermoplastic elatomer (TPE) | |

|---|---|

|

Operating Temperature |

-40 to 80ºC |

|

Mechanical Strength |

Good |

|

Abrasion Resistance |

Good / Excellent |

|

Flex Resistance |

Good / Excellent |

|

Low Temp. Flexibility |

Good |

|

Ozone/Weather Resistance |

Excellent |

|

Water Resistance |

Good |

|

Impermeability to Gases |

Good |

|

Oil Resistance |

Poor / Fair |

|

Fuel Resistance |

Poor |

|

Resistance to Dilute Acid |

Fair |

|

Resistance to Dilute Alkali |

Fair |

|

Special Properties |

- |

| Vamac (AEM) | |

|---|---|

|

Operating Temperature |

-30 to 175ºC |

|

Mechanical Strength |

Fair / Good |

|

Abrasion Resistance |

Good |

|

Flex Resistance |

Fair / Good |

|

Low Temp. Flexibility |

Fair |

|

Ozone/Weather Resistance |

Excellent |

|

Water Resistance |

Excellent |

|

Impermeability to Gases |

Good / Excellent |

|

Oil Resistance |

Good |

|

Fuel Resistance |

Poor / Fair |

|

Resistance to Dilute Acid |

Fair |

|

Resistance to Dilute Alkali |

Poor |

|

Special Properties |

Non-Halogen / Low smoke emission |

| Viton (FKM) | |

|---|---|

|

Operating Temperature |

-20 to 250ºC |

|

Mechanical Strength |

Good |

|

Abrasion Resistance |

Good |

|

Flex Resistance |

Poor / Fair |

|

Low Temp. Flexibility |

Poor / Fair |

|

Ozone/Weather Resistance |

Excellent |

|

Water Resistance |

Excellent |

|

Impermeability to Gases |

Good / Excellent |

|

Oil Resistance |

Excellent |

|

Fuel Resistance |

Excellent |

|

Resistance to Dilute Acid |

Good |

|

Resistance to Dilute Alkali |

Fair |

|

Special Properties |

Heat and chemical resistance |