+44 (0)1355 907 160

sales@bovill-boyd.co.uk

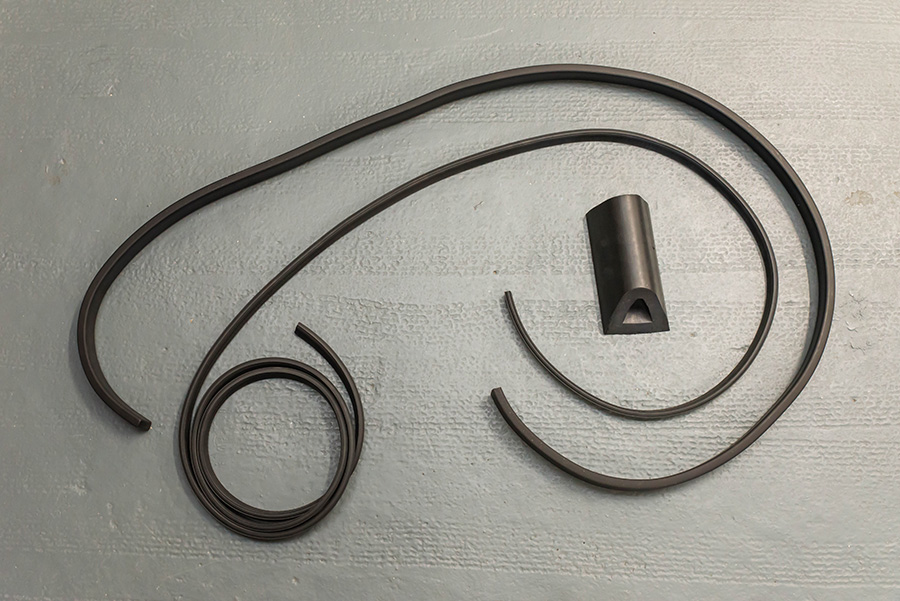

Rubber Extrusions

Rubber Extrusions

Bovill & Boyd have, for many years, been supplying rubber extrusions to various industries including marine, rail, oil & gas, automotive, domestic appliance manufacture, defence and shipbuilding. As a result we have access to tooling to produce a large number of standard profiles including:

- Strips and cord

- Tubing

- Glazing profiles

- Fender

Extrusions can be supplied in almost any size, from large rugged profiles used in subsea applications to precision profiles used for sealing in small spaces. Extrusions can be supplied in lengths to suit your application or can be supplied in continuous length, cut length and joined, or fabricated to form moulded corners to produce items such as:

- Watertight door seals

- Window seals

- Container door seals

- Hatch seals

- Inflatable seals

We can manufacture new extrusions from your drawing or by reverse engineering from a sample.We can identify materials from an existing sample or advise on a suitable formulation to suit your application. Many factors have to be considered when choosing an appropriate material to produce a part that is fit for purpose:

- Will it be exposed to weathering or ozone

- What temperature range will the material be exposed to?

- What chemicals will the component come into contact with? Any oils or fuels?

- Should the material protect against noise or vibration?

- Should the component be conductive, insulating or anti-static?

These, and other processing and application factors, will be considered by our Rubber Technologists when advising on a suitable compound for your project. If no compound exists that meets your requirements exactly then we can formulate a new one in-house. That way, we can work closely with you to ensure you get the product that you need in a timely and cost effective manner.

Materials include – silicone, nitrile, EPDM, Neoprene – standard & FR, EMC Resistant

Rubber Extrusions Produced to various British Standards

Solid & Sponge Extrusions available

Should you require more technical data or material specifications please contact our Sales Team on 01355 907161.

OUR RUBBER EXTRUSIONS FACILITY SUPPLIES THE AUTOMOTIVE, DOMESTIC APPLIANCE, CONSUMER ELECTRONICS, LEISURE, PACKAGING AND ELECTRICAL SECTORS.

We have the expertise to adapt and supply any sector with products for a diverse range of applications using a range of commodity and engineering material grades.

We also welcome enquiries for moulding work requiring secondary, value adding operations such as assembly, printing and ultrasonic welding.